Revers: Modular System Panels

Modular PC system for roofing

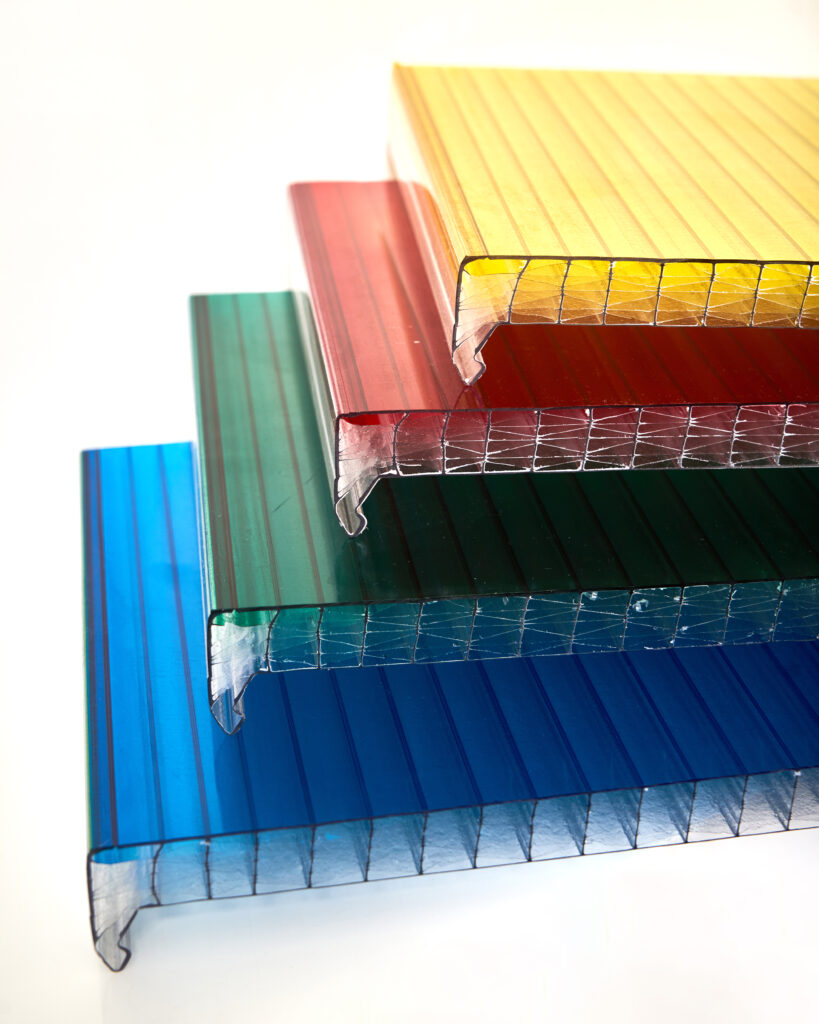

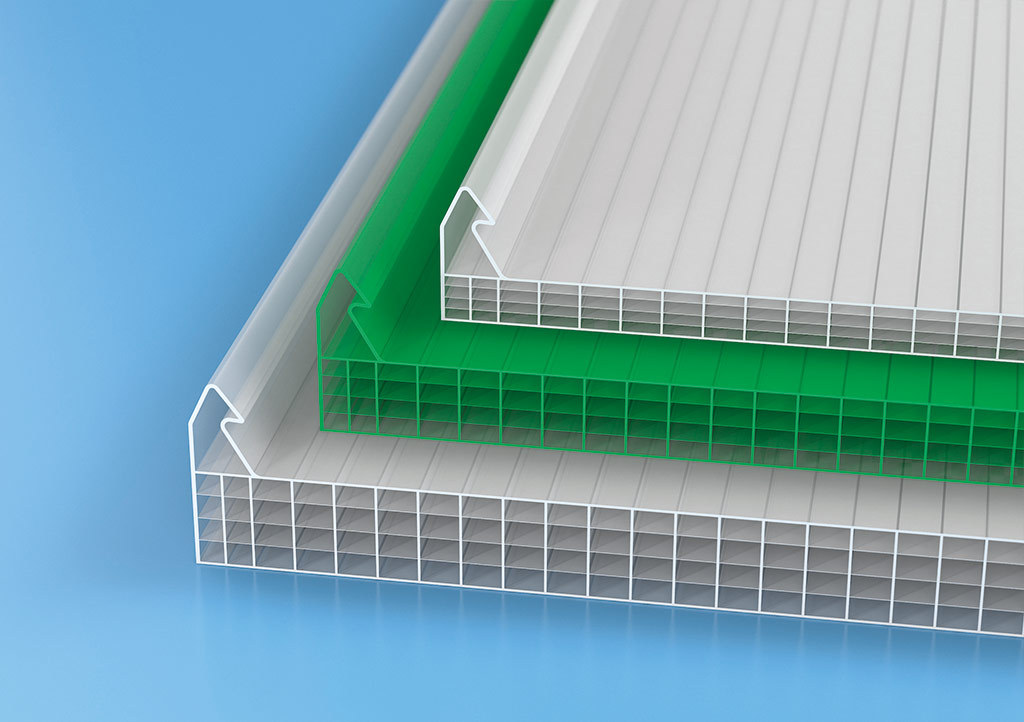

REVERS is an innovative modular polycarbonate system that allows the realization of roofs and vertical walls thanks to joining profile connecting the panels to each other.

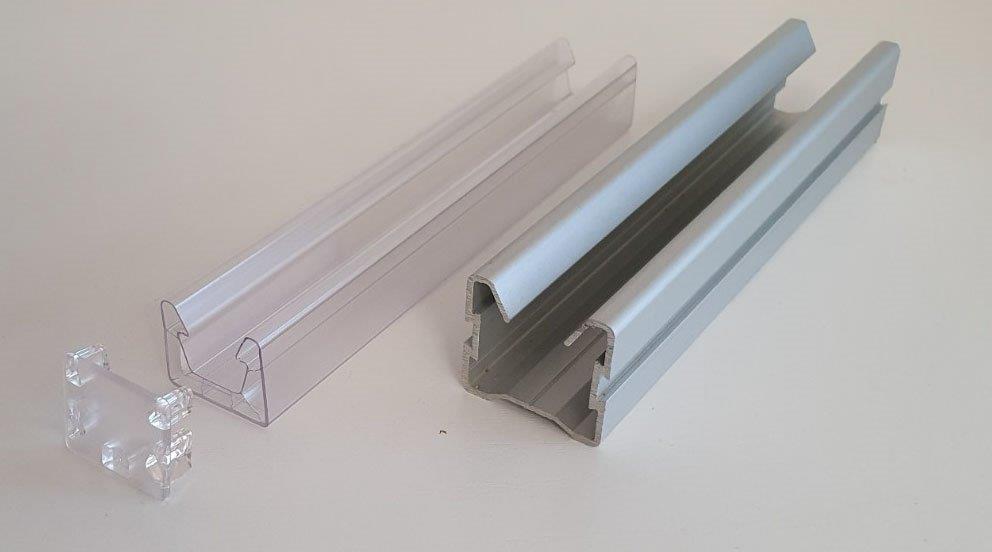

These joining profiles can be made of polycarbonate, to achieve maximum transparency of the solution without visible visual interruption, or aluminum, to ensure greater load resistance.

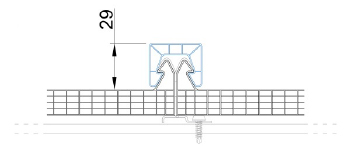

The interlocking joning system between the panel and the profile, without any fixing through the polycarbonate, allows also:

- to reduce the typical noise of polycarbonate systems when elements expad / shrink due to temperature variations

- install solutions with considerable lengths of panels without risk of breakage at the fixing points

The ends of the panels are sealed with aluminium adhesive tape or thermo sealed (max 16 mm thickness).

The different joining profiles required for the installation that panels are respectively:

- with teeth upwards with polycarbonate joining profile installed outside

- with teeth downwards with aluminium joining profile installed inside

A complete range of accessories makes it possible to create aesthetically pleasing solutions.

All panels of REVERS 600 range are produced with standard two UV protected sides while panels of REVERS 1000 range are produced with standard one UV protected side (on request also this one can have two UV protected sides).

For installation, watch the video

Request product datasheetRevers articles

| REVERS 600/8 5W | |

|---|---|

| Thickness | 8 mm |

| Module width | 595 mm (± 5 mm) |

| Cell size | 8 mm |

| Tooth Length | 26,5 mm |

| Length | On request |

All dimensions are subject to production tolerances

| REVERS 600/10 5W | |

|---|---|

| Thickness | 10 mm |

| Module width | 600 mm (± 5 mm) |

| Cell size | 8 mm |

| Tooth Length | 28,5 mm |

| Length | On request |

All dimensions are subject to production tolerances

| REVERS 600/12 5W | |

|---|---|

| Thickness | 12 mm |

| Module width | 600 mm (± 5 mm) |

| Cell size | 8 mm |

| Tooth Length | 30,5 mm |

| Length | On request |

All dimensions are subject to production tolerances

| REVERS 600/16 5W | |

|---|---|

| Thickness | 16 mm |

| Module width | 600 mm (± 5 mm) |

| Cell size | 8 mm |

| Tooth Length | 34,5 mm |

| Length | On request |

All dimensions are subject to production tolerances

| REVERS 600/20 5W | |

|---|---|

| Thickness | 20 mm |

| Module width | 600 mm (± 5 mm) |

| Cell size | 8 mm |

| Tooth Length | 38,5 mm |

| Length | On request |

All dimensions are subject to production tolerances

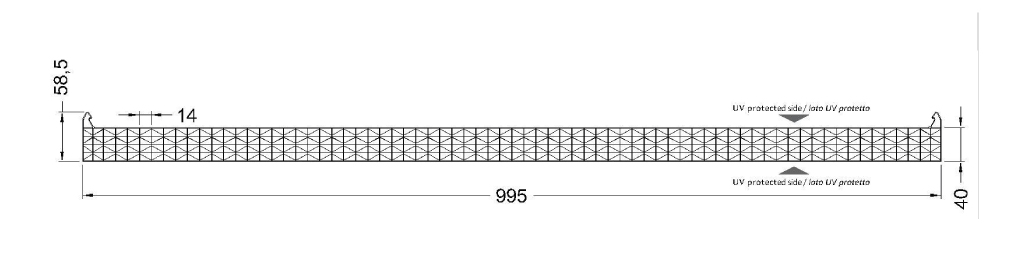

| REVERS 1000/25 XX | |

|---|---|

| Thickness | 25 mm |

| Module width | 995 mm (± 5 mm) |

| Cell size | 14 mm |

| Tooth Length | 43,5 mm |

| Length | On request |

All dimensions are subject to production tolerances

| REVERS 1000/32 XX | |

|---|---|

| Thickness | 32 mm |

| Module width | 995 mm (± 5 mm) |

| Cell size | 14 mm |

| Tooth Length | 50,5 mm |

| Length | On request |

All dimensions are subject to production tolerances

| REVERS 1000/40 XX | |

|---|---|

| Thickness | 50 mm |

| Module width | 995 mm (± 5 mm) |

| Cell size | 14 mm |

| Tooth Length | 58,5 mm |

| Length | On request |

All dimensions are subject to production tolerances

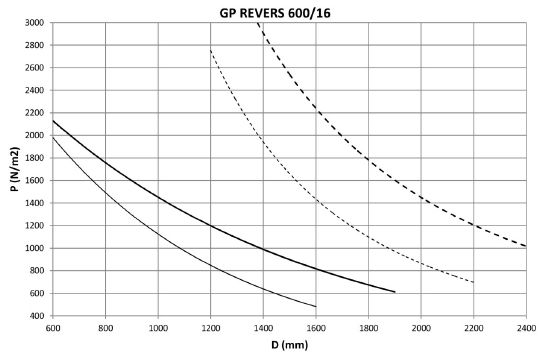

Revers installation

D (mm)

| Loading table | |||

|---|---|---|---|

| P | = uniform distributed load | D | = distance between supports |

| = pressure load with polycarbonate joining profile | = suction load with polycarbonate joining profile | ||

| = pressure load with aluminium joining profile | = suction load with aluminium joining profile | ||

Accessories fot Revers

Installation tips

- be sure the uv protected side faces out

- revers panels must be securely fastened to the supporting structure, with suitable fasteners and a correct distribution of them on the sheet

- supports should be free from anything that may compromise the integrity of the sheets both in the installation phase and during the normal life cycle of the product

Safety

- don’t walk directly on the panels during both installation and maintenance

- to access the roof using suitable runways

- during the operations comply with all regulations concerning safety at work regulations in individual countries

Handling, storage, maintenance

- revers panels can be cut with jigsaws, circular saws, hand saws, making sure that the sheet is properly constrained during cutting to prevent vibrations

- the pallets can be stacked only for a short period of time

- the material must be stored in a protected area from direct sunlight and other heat sources

- do not stack other weights

- periodically clean the outer surfaces of the sheets using neutral detergent and water, paying particular attention not to scratch the surface of the sheets with abrasive, razor blades or other sharp tools in order not to damage the uv protection layer

- avoid contact with chemicals